Maple Sap Vacuum System

Maple sap vacuum system. Turn on a small heat source to prevent the insulated pump box and the pump from ever freezing. The concept is simple. Download resource 1457 MB.

Turn on the diaphragm pump when temperatures rise above freezing to pull sap from the trees. The vacuum system operates on the following basic principles. New York State Maple Tubing and Vacuum System Notebook A comprehensive guide to setting up and maintaining tubing systems for sap production.

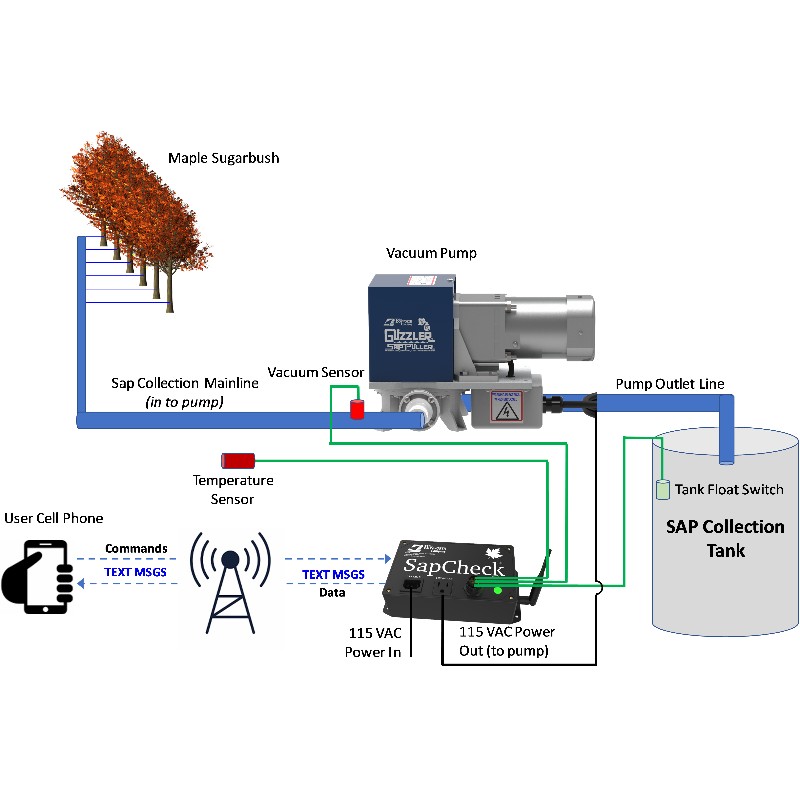

When using tubing can do more taps and get more sap per tap if you use vacuum. Our S4 Diaphragm Pump Controller System is an automatically controlled vacuum system designed to draw sap through a tubing system from maple trees and significantly increase sap yield for the small maple producer without requiring manual intervention. Considering it takes about 43 gallons of sap to make 1 gallon of maple syrup most farmers find the system a significant improvement.

The more modern way of collecting maple sap to produce maple syrup is with tubing systems. Often cheaper to set up initially than buckets. For maple farms.

Rollerflex Vacuum Discharge Hose -. The higher the vacuum pressure at the tree the greater the yield response. Re-adjusting the vacuum control while the system has leaks can cause damage to pumps and possibly motors once freezing occurs and vacuum levels spike in absence of the leak.

Maple syrup is a natural sweetener and a delicacy produced in. Research has shown that adding vacuum to a maple tubing system can increase sap production 50 to over 200 over a maple season. The heart of the system is a low cost diaphragm pump that increases vacuum and resulting sap.

Instead of relying on buckets attached to trees to collect the maple sap maple farms have shifted to a more high-tech methodvacuuming sap straight out of the trees. The vacuum in the system causes the gases in the sap to form bubbles that carry the sap up to the higher line where it can then drain out by gravity.

When using tubing can do more taps and get more sap per tap if you use vacuum.

Maple syrup is a natural sweetener and a delicacy produced in. If the vacuum level drops when the valves of the maple sap tubing system are opened go to the woods and find the leaks. When using tubing do not have to empty buckets. For maple farms. Humidity Trap 2 Lapierre. Turn on a small heat source to prevent the insulated pump box and the pump from ever freezing. Means of main minerals organic acids sugars physico-chemical characteristics and microbial counts in maple sap collected with control vacuum level 20 InHg and high-vacuum level 28 InHg in the tubing system with respective P-values. Considering it takes about 43 gallons of sap to make 1 gallon of maple syrup most farmers find the system a significant improvement. When using tubing can do more taps and get more sap per tap if you use vacuum.

Sap flow in 2010 was lowmoderate for most of the season and never truly challenged any of the systems. Electric Sap Puller Single Diaphragm Pump. With sap yields being less and less reliable however many in the maple industry are employing industrial vacuum systems to bridge this gap and draw more sap from the trees. The concept is simple. The heart of the system is a low cost diaphragm pump that increases vacuum and resulting sap. The vacuum system operates on the following basic principles. Our S4 Diaphragm Pump Controller System is an automatically controlled vacuum system designed to draw sap through a tubing system from maple trees and significantly increase sap yield for the small maple producer without requiring manual intervention.

Post a Comment for "Maple Sap Vacuum System"